Biochar production has gained significant attention in recent years due to its environmental benefits and versatile applications. A biochar machine, designed to convert organic waste into high-value biochar, presents a viable investment opportunity for a range of industries. Biochar, a form of charcoal with unique properties, is used in agricultural, industrial, and environmental sectors. This article explores the types of businesses best suited for investing in biochar machines, highlighting their potential applications, revenue streams, and environmental advantages.

Agricultural Enterprises

One of the primary industries that can benefit from investing in a biochar making machine is agriculture. Biochar is recognized for its ability to improve soil quality by enhancing nutrient retention, increasing water-holding capacity, and promoting soil aeration. These characteristics make it a valuable amendment for both small-scale farms and large agricultural operations. By incorporating biochar into the soil, farmers can improve crop yields while reducing their dependency on synthetic fertilizers, thus lowering input costs.

For businesses in agriculture, particularly those involved in organic farming or sustainable practices, biochar provides an environmentally friendly alternative to chemical soil enhancers. Additionally, the production of biochar from agricultural waste, such as crop residues and plant matter, allows farmers to utilize waste materials effectively, further contributing to cost savings and waste reduction.

Farmers looking to improve soil health and sustainability will find biochar machines to be a valuable investment, not only enhancing productivity but also aligning with modern environmental and sustainability goals.

Waste Management Companies

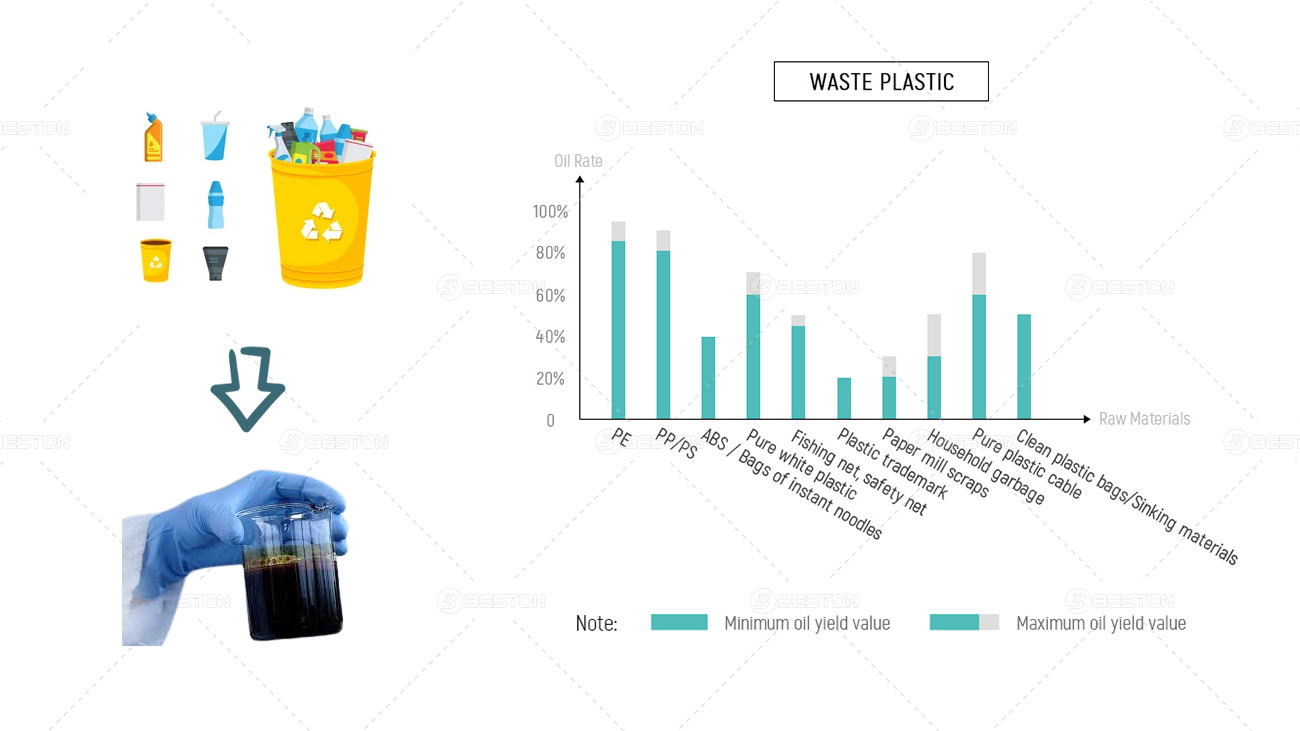

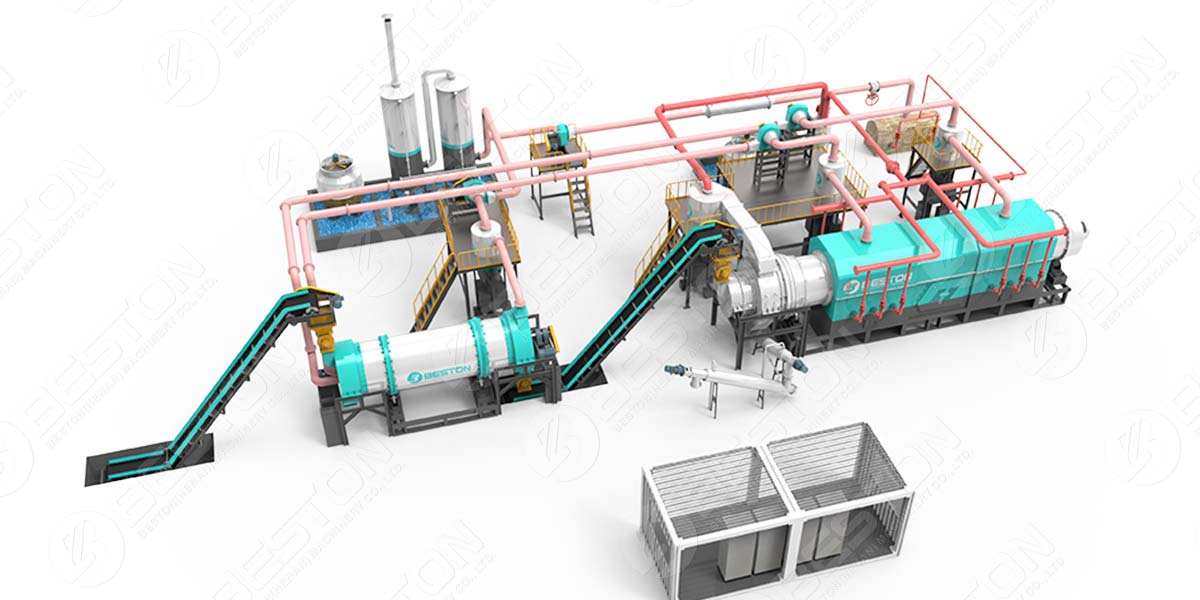

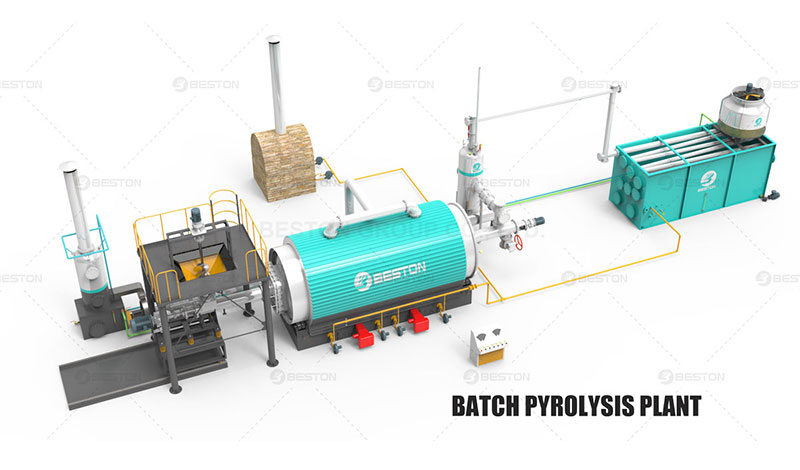

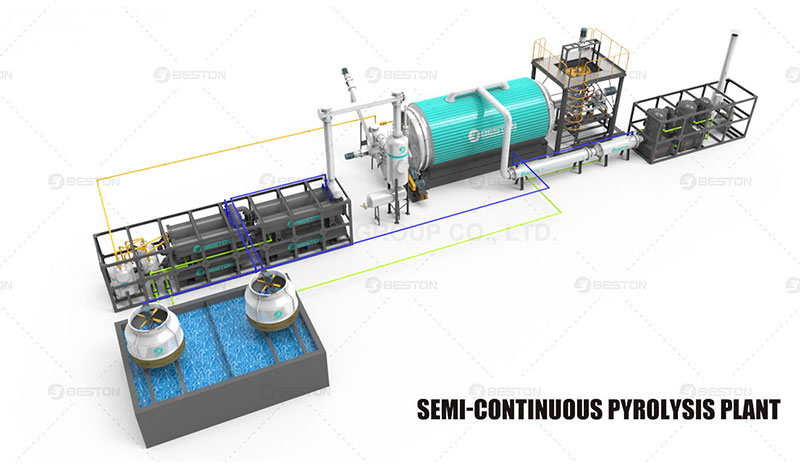

Waste management companies are another sector that stands to gain from biochar production. The increasing global focus on waste reduction and sustainable disposal methods has opened new avenues for businesses to manage waste more efficiently. Organic waste, such as wood chips, agricultural residue, and even some industrial waste, can be converted into biochar through pyrolysis. By investing in pyrolysis machine for biochar, waste management companies can transform waste streams into valuable by-products, reducing landfill dependency and contributing to the circular economy.

The pyrolysis process used in biochar production also has the added benefit of producing energy in the form of syngas, which can be harnessed to power the biochar production process itself, reducing energy costs. Additionally, the carbon-neutral nature of biochar production helps waste management companies enhance their environmental footprint and sustainability credentials, appealing to an increasingly eco-conscious consumer base.

Environmental and Carbon Offset Initiatives

Environmental businesses focused on carbon offset and climate change mitigation are prime candidates for investing in biochar reactor for sale. Biochar has been identified as an effective method for sequestering carbon, a critical step in addressing global climate change. The process of creating biochar locks carbon into a stable form that can be stored in the soil for centuries, preventing it from re-entering the atmosphere as carbon dioxide.

For businesses involved in carbon offset programs or carbon credit trading, the production of biochar offers an additional revenue stream. These businesses can generate and sell carbon credits based on their biochar production, leveraging the environmental benefits of biochar to meet carbon reduction goals. Furthermore, biochar’s ability to reduce greenhouse gas emissions, improve soil health, and prevent land degradation positions it as a valuable tool for businesses seeking to promote environmental sustainability.

Renewable Energy Companies

Renewable energy companies can also find value in biochar machines due to the potential for energy generation during the pyrolysis process. Pyrolysis not only produces biochar but also generates syngas, which can be used as a renewable energy source. This syngas can be utilized to power the biochar machine or converted into electricity or heat for external use. As renewable energy becomes increasingly important in the transition away from fossil fuels, companies that integrate biochar production into their operations can capitalize on both sustainable energy generation and the sale of biochar as a valuable product. If you have investment needs, please contact Beston Group Co., Ltd.

Moreover, biochar’s applications as a soil amendment in renewable energy sectors like bioenergy crop cultivation further solidify its value. The combination of biochar and renewable energy production represents a comprehensive approach to sustainable resource management.

Landscaping and Horticulture

Landscaping and horticultural businesses can also benefit from biochar production. Biochar’s ability to enhance soil fertility, improve root development, and increase plant growth makes it highly valuable for landscaping projects and horticultural applications. Whether used in urban landscaping, golf course maintenance, or large-scale commercial landscaping, biochar can significantly improve soil conditions, particularly in poor or degraded soils.

In horticulture, biochar is widely used in the cultivation of plants such as vegetables, fruits, and flowers. It improves nutrient retention, reduces the need for chemical fertilizers, and increases water efficiency—qualities that make biochar an attractive option for nurseries and greenhouses.

Landscaping companies seeking to offer eco-friendly services or differentiate themselves with sustainable products can leverage biochar as a unique selling point, adding value to their offerings and appealing to environmentally-conscious consumers.

Industrial Manufacturing

The industrial manufacturing sector can also benefit from biochar machines, especially in industries focused on sustainable practices or waste reduction. Biochar is used in various industrial processes, including water filtration, pollution control, and as a raw material in the production of activated carbon. Industrial manufacturing businesses that focus on producing eco-friendly products or offering waste reduction services can use biochar to enhance their sustainability efforts while benefiting from the commercial applications of biochar.

Furthermore, biochar’s high surface area and porous nature make it an excellent material for use in filtration and adsorption processes, such as in air or water purification systems. Industries involved in water treatment, air quality management, and chemical manufacturing may find biochar to be a valuable addition to their operations.